The Making of Arduino

Arduino

How five friends engineered a small circuit board that’s taking the DIY world by storm

The picturesque town of Ivrea, which straddles the blue-green Dora Baltea River in northern Italy, is famous for its underdog kings. In 1002, King Arduin became the ruler of the country, only to be dethroned by King Henry II, of Germany, two years later. Today, the Bar di Re Arduino, a pub on a cobblestoned street in town, honors his memory, and that’s where an unlikely new king was born.

The bar is the watering hole of Massimo Banzi, the Italian cofounder of the electronics project that he named Arduino in honor of the place. Arduino is a low-cost microcontroller board that lets even a novice do really amazing things. You can connect an Arduino to all kinds of sensors, lights, motors, and other devices and use easy-to-learn software to program how your creation will behave. You can build an interactive display or a mobile robot and then share your design with the world by posting it on the Net.

|

| The Arduino core team [from left]—David Cuartielles, Gianluca Martino, Tom Igoe, David Mellis, and Massimo Banzi—get together at Maker Faire in New York City.(Photo: Randi Silberman Klett) |

Released in 2005 as a modest tool for Banzi’s students at the Interaction Design Institute Ivrea (IDII), Arduino has spawned an international do-it-yourself revolution in electronics. You can buy an Arduino board for just about US $30 or build your own from scratch: All hardware schematics and source code are available for free under public licenses. As a result, Arduino has become the most influential open-source hardware movement of its time.

The little board is now the go-to gear for artists, hobbyists, students, and anyone with a gadgetry dream. More than 250 000 Arduino boards have been sold around the world—and that doesn’t include the reams of clones. "It made it possible for people do things they wouldn’t have done otherwise," says David A. Mellis, who was a student at IDII before pursuing graduate work at the MIT Media Lab and is the lead software developer of Arduino.

|

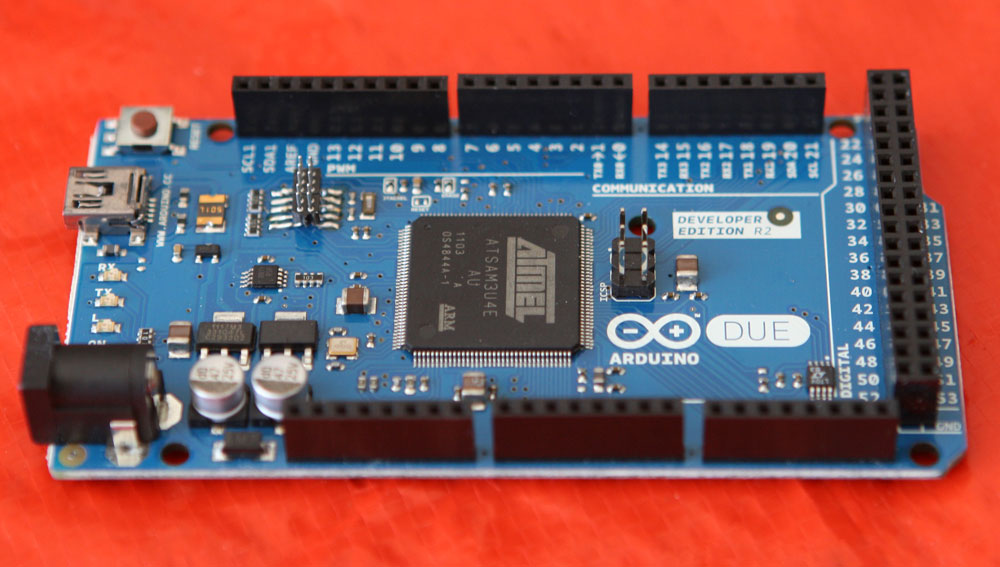

| The team recently unveiled the Arduino Due, a board with a 32-bit Cortex-M3 ARM processor that offers more computing power for makers with complex projects (Photo: Randi Silberman Klett) |

There are Arduino-based breathalyzers, LED cubes, home-automation systems, Twitter displays, and even DNA analysis kits. There are Arduino parties and Arduino clubs. Google has recently released an Arduino-based development kit for its Android smartphone. As Dale Dougherty, the editor and publisher of Make magazine, the bible of DIY builders, puts it, Arduino has become "the brains of maker projects."

But Arduino isn’t just an open-source project that aims to make technology more accessible. It’s also a start-up company run by Banzi and a group of friends, and it’s facing a challenge that even their magic board can’t solve: how to survive success and grow. "We need to make the next jump," Banzi tells me, "and become an established company."

Arduino rose out of another formidable challenge: how to teach students to create electronics, fast. It was 2002, and Banzi, a bearded and avuncular software architect, had been brought on by IDII as an associate professor to promote new ways of doing interactive design—a nascent field sometimes known as physical computing. But with a shrinking budget and limited class time, his options for tools were few.

Like many of his colleagues, Banzi relied on the BASIC Stamp, a microcontroller created by California company Parallax that engineers had been using for about a decade. Coded with the BASIC programming language, the Stamp was like a tidy little circuit board, packing the essentials of a power supply, a microcontroller, memory, and input/output ports for attaching hardware. But the BASIC Stamp had two problems, Banzi discovered: It didn’t have enough computing power for some of the projects his students had in mind, and it was also a bit too expensive—a board plus basic parts could cost about US $100. He also needed something that could run on Macintosh computers, which were ubiquitous among the IDII designers. What if they could make a board that suited their needs themselves?

Banzi had a colleague from MIT who had developed a designer-friendly programming language called Processing. Processing was rapidly gaining popularity because it allowed even inexperienced programmers to create complex—and beautiful—data visualizations. One of the reasons for its success was an extremely easy-to-use integrated development environment, or IDE. Banzi wondered if they could create similar software tools to code a microcontroller instead of graphics on a screen.

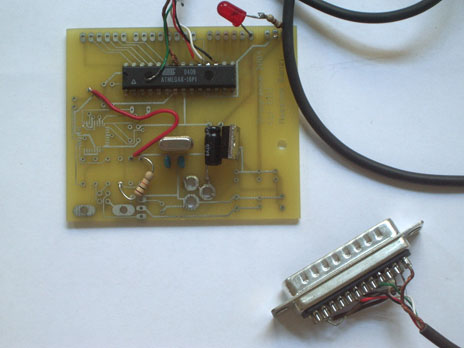

A student in the program, Hernando Barragán, took the first steps in that direction. He developed a prototyping platform called Wiring, which included both a user-friendly IDE and a ready-to-use circuit board. It was a promising project that continues to this day, but Banzi was already thinking bigger: He wanted to make a platform that was even simpler, cheaper, and easier to use.

|

| The first prototype board, made in 2005, was a simple design, and it wasn’t called Arduino. Massimo Banzi would coin the name later that year (Photo: Massimo Banzi) |

Banzi and his collaborators were strong believers in open-source software. Since the purpose was to create a quick and easily accessible platform, they felt they’d be better off opening up the project to as many people as possible rather than keeping it closed. Another factor that contributed to that decision was that after operating for five years, IDII was running out of funds and was going to close its doors. Faculty members feared their projects would not survive or would be misappropriated. "So we said, ‘Forget it,’ " Banzi recalls. " ‘Let’s make it open source.’ "

The open-source model had long been used to fuel innovation for software, but not hardware. To make it work, they had to find an appropriate licensing solution that could apply to their board. After some investigation, they realized that if they simply looked at their project differently, they could use a license from Creative Commons, the nonprofit group whose agreements are normally used for cultural works such as music and writing. "You could think of hardware as piece of culture you want to share with other people," Banzi says.

To make the board, the group had a specific, student-friendly price as their goal: $30. "It had to be the equivalent of going out to dinner at a pizza place," Banzi says. They also wanted to make it quirky, something that would stand out and be cool-looking to erudite geeks. If other boards were often green, they’d make theirs blue; while some manufacturers economized on input and output pins, they’d add plenty to their board. As a final touch, they added a little map of Italy on the back of the board. "A lot of the design choices are weird for a real engineer," Banzi says with a knowing laugh, "but I’m not a real engineer, so I did it in a silly way!"

For one of the "real" engineers on the team, Gianluca Martino, the unconventional, meatball-surgery approach to circuit board design was enlightening. Martino describes it as a "new way of thinking about electronics," he says, "not in an engineering way, where you have to count electrodes, but a do-it-yourself approach."

The product the team created consisted of cheap parts that could easily be found if users wanted to build their own boards, such as the ATmega328 microcontroller. But a key decision was to ensure that it would be, essentially, plug-and-play: something someone could take out of a box, plug into a computer, and use immediately. Boards such as the BASIC Stamp required that DIYers shell out for half a dozen other items that added to the total cost. But for theirs, a user could just pull out a USB cable from the board and connect it to a computer—Mac or PC—to program the device.

"The philosophy behind Arduino is that if you want to learn electronics, you should be able to learn as you go from day one, instead of starting by learning algebra," says another member of the team, telecommunications engineer David Cuartielles.

The team would soon put that philosophy to the test. They handed 300 blank printed circuit boards to the IDII students with a simple directive: Look up the assembly instructions online, build your own board, and use it for something. One of the first projects was a homemade alarm clock that hung from the ceiling by a cable. Whenever you hit the snooze button, the clock would rise tauntingly higher into the air until you just had to get up.

Soon other people heard about the boards. And they wanted one. The first customer was a friend of Banzi’s, who ordered one unit. The project was starting to take off, but one major thing was missing—a name for their invention. One night over drinks at the local pub, it came to them: Arduino, just like the bar—and the king.

Word of Arduino quickly spread online, with no marketing or advertising. Early on, it attracted the attention of Tom Igoe, a professor of physical computing at the Interactive Telecommunications Program at New York University and today a member of the core Arduino team. Igoe had been teaching courses to nontechnical students using the BASIC Stamp but was impressed by Arduino’s features. "They had the assumption that you didn’t know electronics and programming, that you didn’t want to configure an entire machine just so you could program a chip—you could just open up the board, press upload, and it works," he says. "I was also impressed with the goal of a $30 price, which made it accessible. This was one of the key factors for me."

In that regard, the success of Arduino owes a lot to the prior existence of Processing and Wiring. Those projects gave Arduino one of its essential strengths: the user-friendly programming environment. Before Arduino, coding a microcontroller brought with it a difficult learning curve. With Arduino, even those with no previous electronics experience gained access to a previously impenetrable hardware world. Now, beginners don’t have to learn much before they can build a prototype that actually works. It’s a powerful movement at a time when some of the most popular gadgets out there work as "black boxes" that are closed and patent protected.

For Banzi, this is perhaps the most important impact of Arduino: the democratization of engineering. "Fifty years ago, to write software you needed people in white aprons who knew everything about vacuum tubes. Now, even my mom can program," Banzi says. "We’ve enabled a lot of people to create products themselves."

Not all engineers love Arduino. The more persnickety ones bemoan the product for dumbing down product creation and flooding the hobbyist market with lackluster goods. Mellis, however, doesn’t see the innovation as devaluing the role of the engineer at all. "By providing a platform that lets the artist or designer get a little way in there, it makes it easier for them to work with engineers and say, ’This is what I want to do,’ " he says. "I don’t think it’s replacing the engineer; it’s just facilitating that collaboration."

To fuel greater adoption of Arduino, the team is exploring how to integrate it more deeply into the education system, from grade schools to colleges. Several universities, including Carnegie Mellon and Stanford, already use Arduino. Mellis has been studying how students and laypeople take to electronics in a series of workshops at the MIT Media Lab. Mellis invites 8 to 10 people to the lab, where they’re given a task to complete over the course of a day. The projects have included building iPod speakers, FM radios, and a computer mouse using some of the same components that Arduino uses.

But spreading the Arduino gospel is only part of the challenge. The team must also keep up with demand for the boards. In fact, the Arduino platform doesn’t consist of one type of board anymore—there’s now an entire family of boards. In addition to the original design, called the Arduino Uno, the new models include a more powerful board called the Arduino Mega, a compact board called the Arduino Nano, a waterproof board called the LilyPad Arduino, and a recently released, Net-enabled board called the Arduino Ethernet.

Arduino has also created its own cottage industry for DIY electronics. There are more than 200 distributors of Arduino products around the world, from large companies such as SparkFun Electronics, in Boulder, Colo., to mom-and-pop operations serving local needs. Banzi recently heard from a man in Portugal who quit his job at the phone company to sell Arduino products from his home. Arduino team member Gianluca Martino, who oversees production and distribution, says they’re working overtime to reach emerging markets such as China, India, and South America. At this point, he says, about 80 percent of the Arduino audience is split between the United States and Europe, with the rest scattered around the world.

Because the team can’t afford to stock hundreds of thousands of boards, they instead produce anywhere from 100 to 3000 per day at a manufacturing facility near Ivrea. The team created a custom system for testing the pins on each board, which for the Uno includes 14 digital I/O pins, 6 analog input pins, and another 6 pins for the power supply—a big quality-assurance challenge when you’re handling thousands of units a day. The Arduino board is inexpensive enough for the team to promise to replace any board that doesn’t work. Martino says the failure rate is below 1 percent.

|

| The Arduino team contracted with a company that can manufacture from 100 to 3000 boards per day at a facility near Ivrea, Italy (Photo: Massimo Banzi) |

The Arduino team is now earning enough to support two of its members as full-time employees and is making plans to bring even more circuit board power to the people. In September, at the Maker Faire, a convention in New York City sponsored by Make magazine, the team launched its first board with a 32-bit processor—an ARM chip—up from the 8-bit one of the past. This will serve the demand for powering more robust peripherals. The MakerBot Thing-O-Matic, for example, is a 3-D printer kit built on Arduino, but it would benefit from a faster processor to achieve more complicated tasks.

Arduino got another boost this year when Google released an Arduino-based developer board for its Android system. Google’s Android ADK, or Accessory Development Kit, is a platform that lets an Android phone interact with motors, sensors, and other devices. You can build an Android app that uses the phone’s camera, motion sensors, touch screen, and Internet connectivity to control a display or robot, for example. Enthusiasts say that the added Android capability opens up the possibilities for Arduino projects even more.

The team is cautious, however, about overcomplicating Arduino. "The challenge is finding a way to accommodate all the different things that people want to do with the platform," Mellis says, "without making it too complex for someone just getting started."

In the meantime, they’re enjoying their unlikely fame. Fans travel from far away just to have a drink at the pub in Ivrea where the phenomenon got its name. "People go to the bar and say, ’We’re here because of the Arduino board,’ " Banzi says. There’s just one problem, he adds with a laugh: The bartenders don’t know what the Arduino board is.

David Kushner

Sem comentários:

Enviar um comentário